Since WORLDDOMEHOUSE uses compressed high-density EPS as its main material, it is one of the most excellent houses in terms of insulation efficiency.

EPS product has as huge advantage to block the heat flow because it is composed of numerous independent air bubbles. Factors affecting the insulation capabilities of EPS products are as follows.

Density : Insulation effect decreases in inverse proportion to density but, gradually increases from a certain level. (about 40㎏/㎥)

Moisture contents : Insulation effect decreases because the heat conductivity increases with higher moisture contents.

Temperature : Heat conductivity decreases as the temperature decreases.

Units representing EPS insulation effect

Heat conductivity (λ, Kcal/m.hr.℃)

Heat conductivity means the quantity of heat (Q) per hour passing through an object with cross section area of 1㎡ and length of 1 meter given a temperature difference of 1℃. In other words, the degree of heat conductivity is a value that can be used to determine how easy the heat can pass through a certain material; a lower value means the material has greater insulation effect.

Thermal resistance (R, ㎡.hr.℃/Kcal)

In actual building design, both heat conductivity of individual materials and respective thicknesses should be calculated; therefore, the values considering both factors are required. Accordingly, the thermal resistance value is mostly used in building design.

* Thermal resistance R=d (thickness) / λ (heat conductivity of the material)

Heat transmission coefficient (K, Kcal/㎡.hr.℃)

This refers to the heat transfer between solid and fluid. More specifically, heat transfer coefficient means the heat transfer which is from indoor air to inner side surface of the insulation material or from the outside surface of the insulation material outdoor air.

Resistance of heat transmission (Rt, ㎡.hr.℃/Kcal)

The reciprocal of heat transmission coefficient is the resistance of heat transmission.

* Resistance of heat transmission coefficient Rt=1÷K=(∑1/a+∑d/λ)

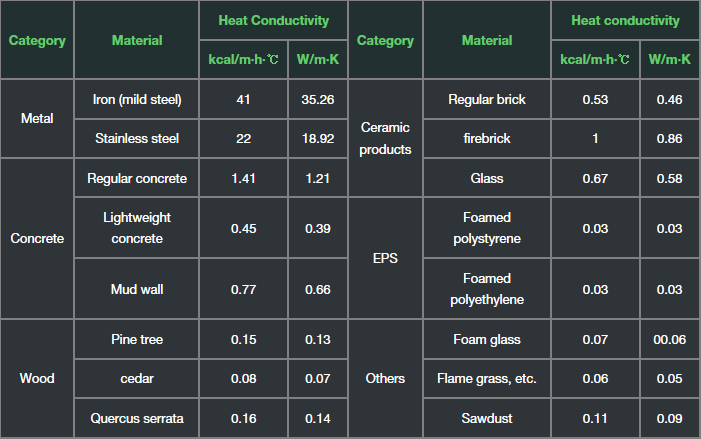

Heat conductivity of each construction material

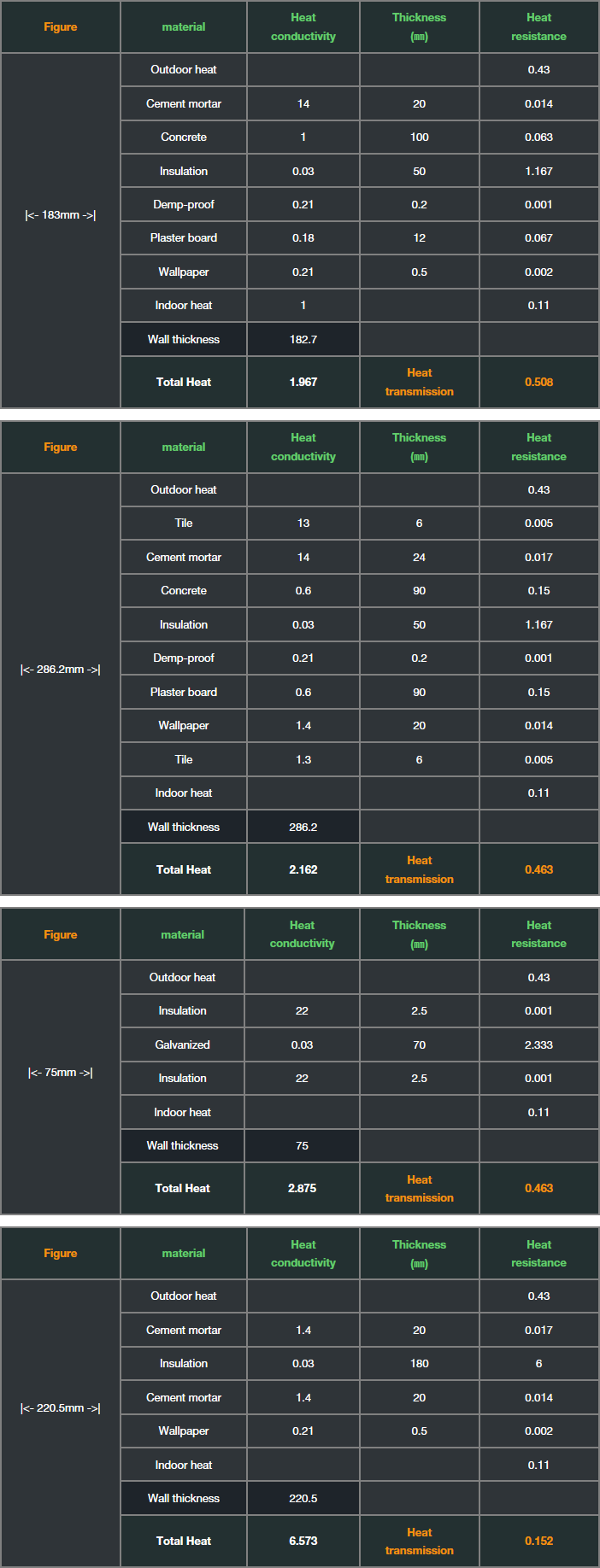

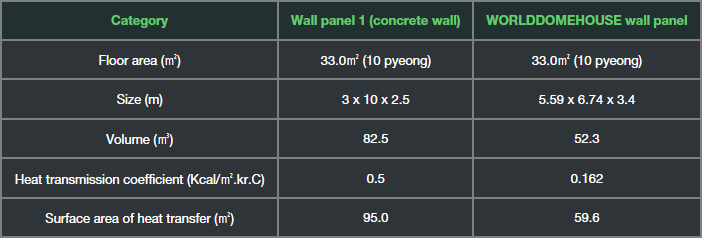

Comparison of heat transmission coefficients between existing wall panel and WORLDDOMEHOUSE wall panel

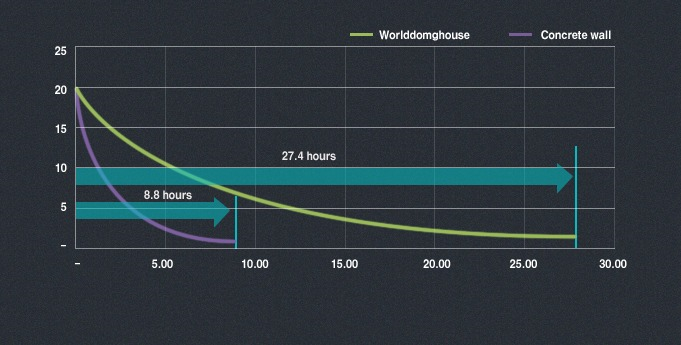

Comparison of time which indoor temperature becomes equal to outdoor temperature

Preconditions

Size of the construction structure and heat transmission coefficient of the wall panel are assumed as follows

Physical properties of indoor air are as follows

Air density: 1.2㎏/㎥, Specific heat at constant pressure: 0.24 kcal/㎏·℃, Specific heat at constant volume: 1.17 kcal/㎏·℃.

Time taken for indoor temperature to become equal to outdoor temperature.

Assuming no heating supplied to the inside of a completely enclosed space and no heat generation device within the space, time taken for the indoor temperature (20℃) to become equal to the outdoor temperature (0℃) is as follows:

Time taken for the indoor temperature of 20℃ to become equal to the outdoor temperature 0℃ is 27.4 hours when the space is fully enclosed with WORLDDOMEHOUSE wall panels without windows; and 8.8 hours in case of concrete wall panels.

If indoor boiler is set to be turned on when the indoor temperature reaches 15℃ and turned off when the temperature reaches 20℃, the boiler turns on every 28 minutes in concrete wall panel house but, in the case of WORLDDOMEHOUSE it turns on every 135 minutes. This means that the number of times of boiler operation per day is 52.4 in concrete wall panel house and 10.6 in WORLDDOMEHOUSE respectively. In short, the number of times of boiler operation in concrete wall panel house is about 5 times bigger than that in WORLDDOMEHOUSE.

If indoor heat generation devices and heat generated by human bodies are considered, the differences become much bigger.

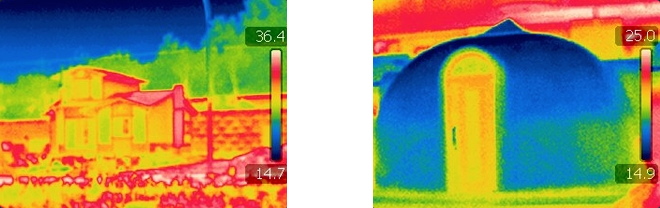

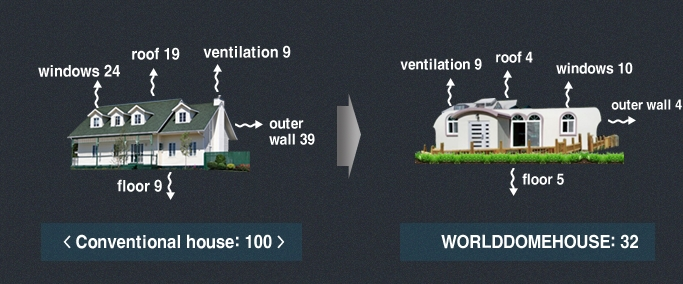

Pictures taken with thermo-graphic camera

< Conventional house > < WORLDDOMEHOUSE >

Compare the heat loss